News & Notes

The Blog ofMID-CONTINENT STEEL AND WIRE

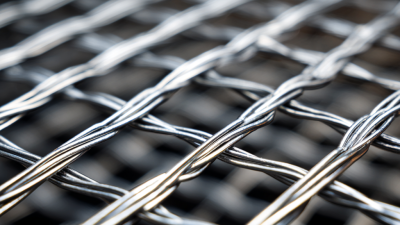

In the realm of manufacturing, wire products have emerged as a vital component driving innovation. Expert Sarah Thompson, a leading figure in the wire products sector, emphasizes, "Adaptability in wire products can lead to groundbreaking solutions." As industry demands evolve, wire products must keep pace with new trends and technologies.

Manufacturers face challenges. Rapid advancements can sometimes outstrip capabilities. New materials and production techniques hold immense potential but require adaptation. Innovations in wire products could redefine manufacturing efficiency and design flexibility. These products can streamline processes, reduce waste, and improve performance.

However, the path forward is not without obstacles. Many companies struggle to implement these innovations effectively. The integration of cutting-edge technologies into existing systems can be daunting. Stakeholders must reflect on their strategies to harness the full potential of wire products in innovative manufacturing solutions.

The wire production landscape is evolving rapidly. Emerging technologies are set to shape manufacturing solutions by 2026. Automation and robotics will play a crucial role. These tools can enhance efficiency and reduce human error. However, challenges remain. Implementing these technologies requires significant investment and training.

Additive manufacturing is another exciting area. This method allows for complex wire shapes that traditional processes can't achieve. It opens new avenues for design and functionality. Yet, achieving the desired quality can be difficult. Manufacturers must adapt their approaches to maintain standards.

Sustainability is also a key trend. Innovations focusing on eco-friendly materials are gaining traction. Companies are exploring recycled inputs and energy-efficient processes. These efforts are not without hurdles. Balancing cost and sustainability remains a puzzle for many. The road ahead is filled with potential but requires thoughtful navigation.

Sustainability is a hot topic in wire manufacturing. Many companies are rethinking their processes. They strive to reduce waste and improve energy efficiency. For example, using recycled materials can significantly lower the carbon footprint. This shift helps create a more eco-friendly product.

Innovative manufacturing solutions are emerging. The use of renewable energy sources is becoming more common. Factories are exploring solar and wind power to operate machinery. However, the transition isn’t always smooth. Initial costs can be high, and not all regions offer support. It requires careful planning and commitment.

Another aspect to consider is production practices. Some firms are adopting lean manufacturing principles. This approach minimizes waste while maximizing productivity. However, it poses a challenge in balancing efficiency with quality. Companies must avoid cutting corners in the pursuit of sustainability. Discrepancies could lead to product failures, impacting customer trust. Embracing sustainability means ongoing evaluation and adjustment.

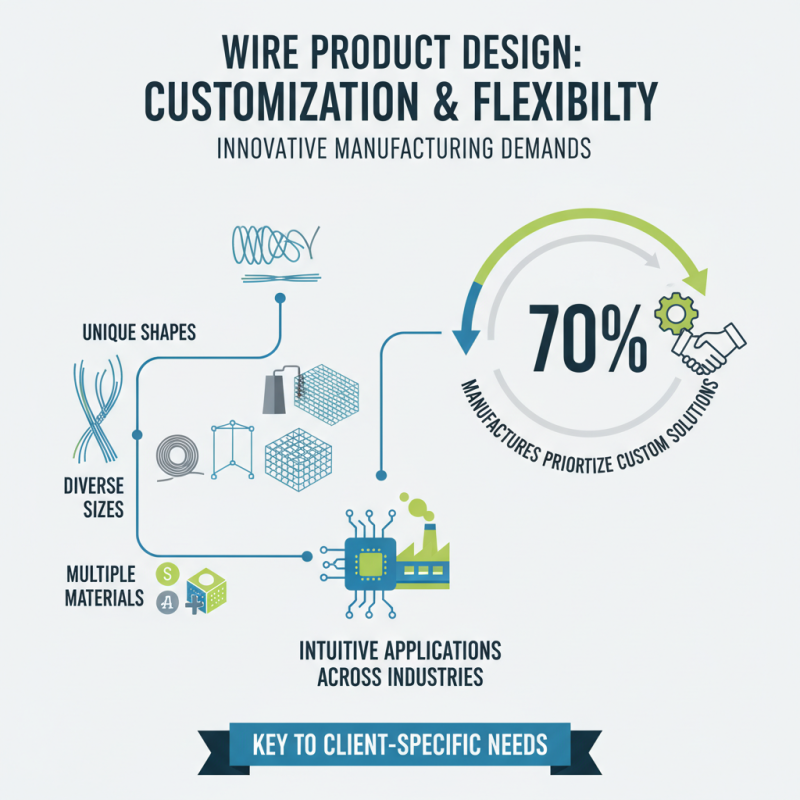

Customization and flexibility in wire product design are more crucial than ever in innovative manufacturing. Recent reports indicate that nearly 70% of manufacturers are prioritizing customized solutions to fit specific client needs. This shift reflects a demand for unique products tailored to intricate specifications. Wire products can now be designed in various shapes, sizes, and materials, aligning with diverse applications across industries.

Flexibility in design enables rapid prototyping and modifications. Many manufacturers embrace computer-aided design (CAD) technologies, allowing for quick adjustments. A study revealed that 55% of companies consider the ability to adapt designs a critical factor in their competitive edge. However, a common challenge remains: balancing customization with production efficiency. Often, excessive customization may lead to longer lead times and increased costs. Striking the right balance requires reflection and ongoing improvement in manufacturing processes.

Incorporating intelligent software has shown promise. These tools facilitate real-time adjustments without extensive manual intervention. But, they also raise concerns about reliability and the potential for errors. As manufacturers navigate these technological advancements, the quest for truly innovative wire products continues. Addressing customization demands while optimizing production flow remains a vital focus.

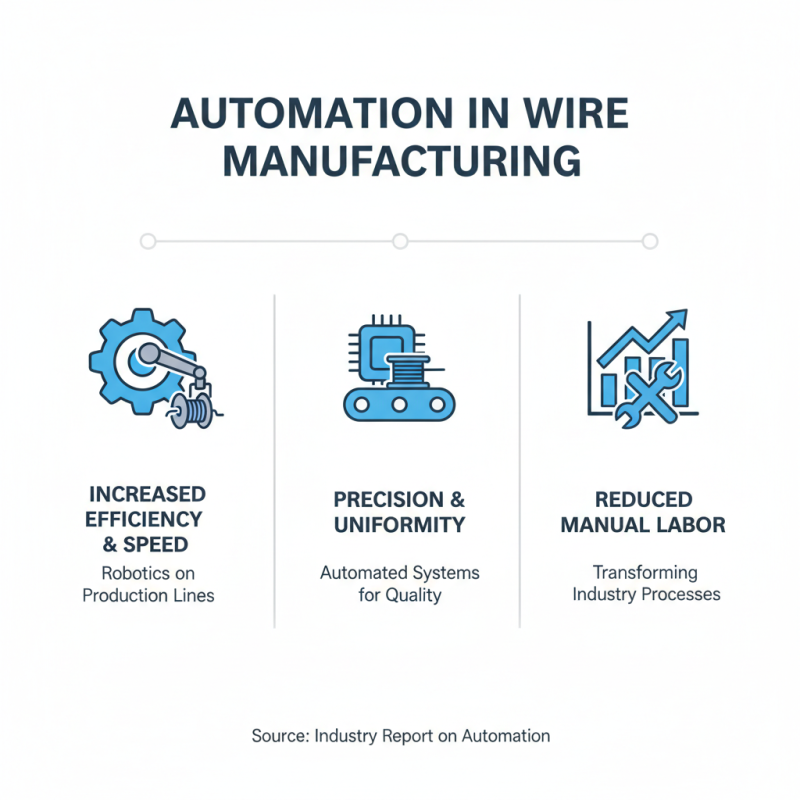

The integration of automation in wire manufacturing processes is transforming the industry. As more manufacturers seek efficiency, automated systems play a crucial role. Robotics are now commonplace on production lines, reducing manual labor and increasing speed. These systems can perform precise tasks, ensuring uniformity in wire products.

Yet, the shift to automation is not without challenges. Some companies struggle with the initial investment in technology. There can be a steep learning curve for staff, leading to potential errors. Understanding data from automated systems requires new skills. These hurdles highlight the need for ongoing training and adaptation.

Manufacturers must also consider the balance between automation and human touch. While machines improve efficiency, human oversight is essential for quality control. The best results often come from a hybrid approach. This situation prompts questions about workforce roles in the future of wire manufacturing. Emphasizing collaboration between man and machine could lead to innovative solutions.

The wire products market is evolving rapidly. Consumer preferences are shifting towards more sustainable and innovative solutions. There’s a clear demand for products that not only serve functional purposes but are also environmentally friendly. Many buyers are now choosing materials that reduce waste and have a lower carbon footprint.

Tip: Consider the materials used in your wire products. Are they recyclable? How do they impact the environment?

Design also plays a crucial role. Customers are looking for aesthetics combined with functionality. Innovative shapes and colors can attract attention. However, striking the right balance between form and practicality can be challenging. Not every design resonates with the target audience.

Tip: Test your designs with potential users. Gather feedback early to identify potential pitfalls.

Customization is another trend on the rise. Consumers want products tailored to their specific needs. This demand can lead to complexities in production. Custom solutions often require more resources and careful planning. It’s essential to stay flexible and responsive to market trends.

Tip: Stay updated on industry trends. Create a feedback loop with customers to improve your product offerings.

If you need more information about our products or you can’t find what you are looking for, please reach us via our contact form and we will get back to you as soon as possible.

© 2022 MID-CONTINENT STEEL AND WIRE, ALL RIGHTS RESERVED | PRIVACY POLICY | PRIVACY POLICY – CALIFORNIA