News & Notes

The Blog ofMID-CONTINENT STEEL AND WIRE

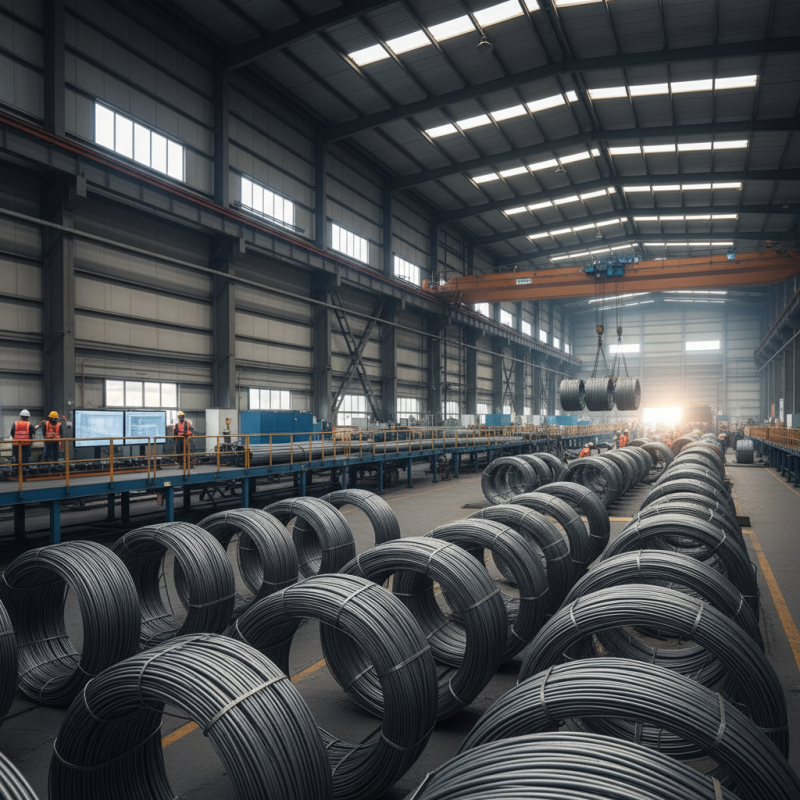

The selection of the appropriate wire rod is crucial for the success of various industrial and construction projects. Wire rods are essential materials utilized in applications ranging from automotive components to construction reinforcements, making their quality and specifications paramount. According to a report by Grand View Research, the global wire rod market size was valued at approximately USD 225 billion in 2020 and is expected to grow significantly, driven by the rising demand in sectors such as manufacturing and infrastructure development.

When choosing the best wire rod for specific projects, factors such as tensile strength, ductility, and corrosion resistance must be carefully considered. Reliable data from the World Steel Association indicates that high-quality wire rods are increasingly favored in constructions that require durability and performance under stress. As the industry continues to evolve, understanding the specific requirements of wire rod grades and types is essential to ensure optimal outcomes in construction quality and longevity. This article will delve into critical considerations for selecting the right wire rod tailored to the unique needs of your projects.

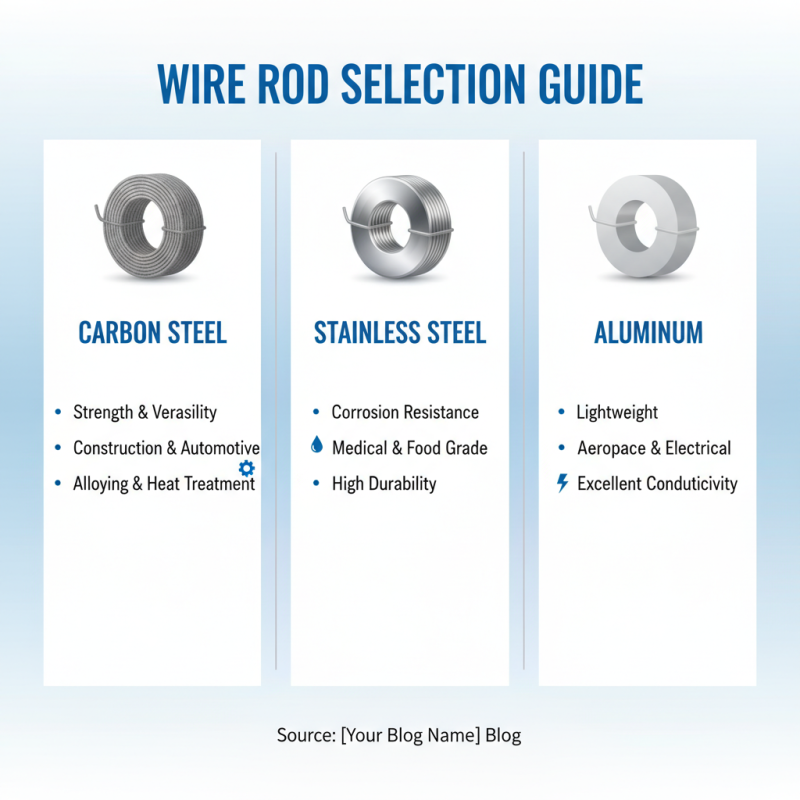

When selecting wire rods for various projects, it’s crucial to understand the different types and their properties to ensure the best outcomes. Wire rods are typically classified based on the materials they are made from, including carbon steel, stainless steel, and aluminum. Carbon steel wire rods are known for their strength and versatility, making them suitable for a wide range of applications, from construction to automotive parts. Their properties can be adjusted through alloying and heat treatment, allowing for various grades that meet specific performance needs.

On the other hand, stainless steel wire rods are renowned for their corrosion resistance, making them ideal for applications exposed to harsh environments. They maintain strength and structural integrity even when exposed to moisture or chemicals. Meanwhile, aluminum wire rods are lightweight and possess good conductivity, making them an excellent choice for electrical applications. Each type of wire rod has unique characteristics, such as tensile strength, ductility, and thermal conductivity, which influence their suitability for different projects. Understanding these properties will aid in making informed decisions that align with the specific requirements of any undertaking.

When selecting wire rod for your projects, several key factors should be taken into consideration to ensure optimal performance and suitability for your intended application. First and foremost, the material composition of the wire rod plays a crucial role. Common materials include carbon steel, stainless steel, and alloyed steels, each offering distinct mechanical properties such as tensile strength, ductility, and corrosion resistance. Depending on the environmental conditions and load requirements of your project, choosing the right material can significantly impact the longevity and effectiveness of the final product.

Another critical factor to evaluate is the diameter and weight of the wire rod. The diameter will influence the flexibility and strength of the wire, determining how it can be used in construction, manufacturing, or crafting. For instance, larger diameters may be necessary for heavy-duty applications, while smaller diameters could be adequate for lighter tasks. It is also important to consider the rod's weight, as this can affect transport and handling during the project phase. Finally, understanding the specific industry standards and certifications related to wire rod can further aid in making an informed decision, ensuring that the materials used will meet necessary safety and quality benchmarks.

| Material Type | Diameter (mm) | Tensile Strength (MPa) | Yield Strength (MPa) | Weight (kg/km) | Surface Treatment |

|---|---|---|---|---|---|

| Carbon Steel | 5.0 | 550 | 350 | 1000 | Galvanized |

| Alloy Steel | 6.0 | 600 | 400 | 1200 | Coated |

| Stainless Steel | 4.0 | 700 | 450 | 950 | Passivated |

| Copper | 3.0 | 210 | 70 | 800 | Natural |

| Low Carbon Steel | 7.0 | 500 | 320 | 1100 | Electroplated |

When selecting wire rod for specific applications, understanding the requirements becomes crucial to ensure that the material meets performance, durability, and aesthetic criteria. Different projects may demand varying specifications in terms of composition, diameter, and mechanical properties. For instance, if the application involves high-strength requirements, opting for wire rod with enhanced tensile strength is essential. Additionally, factors such as corrosion resistance and fatigue performance should be evaluated, particularly for projects exposed to harsh environments or cyclic loading conditions.

Another important aspect to consider is the suitability of wire rod materials for their intended use. For example, wire rods utilized in construction might call for steel with properties that offer excellent weldability and formability, while those destined for automotive components need to provide superior tensile strength and ductility. Furthermore, understanding the manufacturing process and how it influences the wire rod's characteristics can help in making an informed decision. This tailored approach ensures that the selected wire rod aligns with the specific demands of your project, contributing to overall success and longevity.

When selecting the best wire rod for your projects in 2025, understanding the differences in material grades and strength standards is crucial. Wire rods are often produced from various metals, with steel being the most prevalent due to its high tensile strength and versatility. The material grade of a wire rod generally indicates its chemical composition and mechanical properties, which directly influence its performance in various applications. Common grades include low carbon, medium carbon, and high carbon steel, each offering distinct benefits.

For example, low carbon steel is malleable and easy to work with, making it ideal for projects requiring forming and bending. In contrast, high carbon steel provides superior strength but can be more challenging to manipulate.

Strength standards are equally important when comparing wire rods, as they determine how well the material can withstand applied forces. These standards are typically expressed in terms of yield strength and tensile strength. Yield strength refers to the amount of stress a material can endure without permanent deformation, while tensile strength indicates the maximum stress that a material can withstand before failure. Understanding these metrics helps in choosing a wire rod that not only meets the specific mechanical demands of your project but also aligns with safety requirements.

By carefully comparing material grades and their corresponding strength standards, you can ensure that the wire rod you choose will provide the necessary performance for your intended applications.

When embarking on a wire rod project, understanding cost analysis is essential for making informed decisions. Wire rods come in various types, each with different pricing structures depending on factors such as material grade, supplier location, and market demand. To accurately budget, it’s crucial to conduct a comprehensive analysis of all potential costs, including transportation, processing, and any additional fees that may arise when dealing with suppliers. Take the time to compare at least three quotes from different suppliers to understand the range of prices available and identify which factors contribute to higher or lower costs.

Tips: Always factor in potential fluctuations in raw material prices due to market changes. Establishing good relationships with suppliers can sometimes yield better pricing or more flexible terms. Furthermore, consider collaborating with suppliers who offer value-added services like technical support or customized solutions, as this can impact the overall cost-effectiveness of your project.

In addition to costs, supplier considerations play a vital role in the selection process. Evaluate potential suppliers not only based on price but also on their reliability, quality of products, and after-sales services. A reputable supplier should provide transparent information about their production practices and quality assurances. This diligence ensures that the wire rod chosen meets the specific needs of your projects and minimizes potential issues down the line.

Tips: Investigate the suppliers' history and read reviews or testimonials from previous customers. A trustworthy supplier will have a solid track record and should be willing to provide references upon request.

If you need more information about our products or you can’t find what you are looking for, please reach us via our contact form and we will get back to you as soon as possible.

© 2022 MID-CONTINENT STEEL AND WIRE, ALL RIGHTS RESERVED | PRIVACY POLICY | PRIVACY POLICY – CALIFORNIA