News & Notes

The Blog ofMID-CONTINENT STEEL AND WIRE

Choosing the right rebar steel for your construction project can be a daunting task. The quality of rebar plays a crucial role in the durability of structures. According to industry expert Dr. James Whitaker, “The right rebar steel ensures a project can withstand the test of time.”

When selecting rebar steel, several factors come into play. These include grade, size, and coating options. Understanding these details is essential. A project might often compromise steel quality for cost. However, this can lead to structural failures in the long run.

It is important to keep in mind regional differences in standards. Not every rebar steel option is suitable for every location. Choose wisely, as the implications can be significant. Every decision made today affects the safety and longevity of the structures we build.

When embarking on a construction project, understanding rebar steel basics is crucial. Rebar, or reinforcing bar, adds strength to concrete structures. It helps prevent cracks and structural failure. Knowing its types and grades is essential for making informed decisions.

Different grades of rebar exist, each with unique properties. For example, Grade 40 rebar offers basic strength, while Grade 60 is stronger and more durable. Sometimes, projects may require a mix of both. Misjudging the strength needed could lead to costly mistakes. Choosing the right size is also vital. Standard diameters range from #3 to #18, catering to various project requirements.

Moreover, consider the environment where the rebar will be used. Corrosion resistance is a factor to weigh, especially in coastal areas. Improper selection may result in premature deterioration. Visual inspection of rebar quality matters too. Look for rust, deformities, or inconsistencies. These aspects can significantly impact the integrity of your construction. Not paying attention here might lead to future regrets.

| Rebar Type | Diameter (mm) | Yield Strength (MPa) | Suggested Use |

|---|---|---|---|

| HRB400 | 12 | 400 | Residential Construction |

| HRB500 | 16 | 500 | Commercial Buildings |

| Epoxy-Coated | 20 | 400 | Corrosive Environments |

| Stainless Steel | 25 | 450 | High Durability |

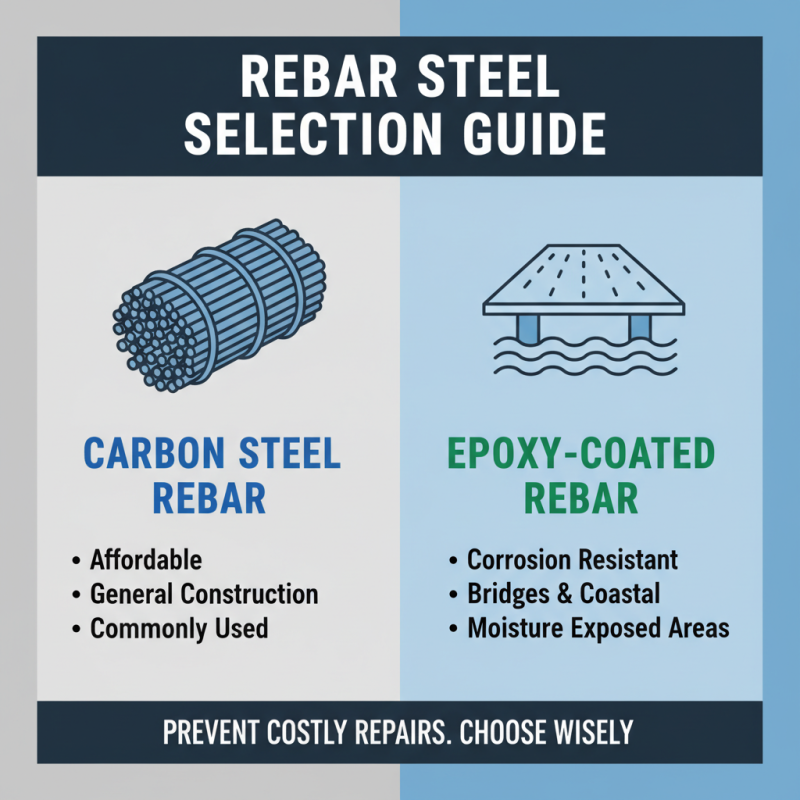

When selecting rebar steel for construction projects, understanding the types and their applications is crucial. The most common type is carbon steel rebar. It is affordable and widely used for general construction. Another type is epoxy-coated rebar. This variation offers excellent corrosion resistance, making it ideal for areas exposed to moisture. Such environments include bridges and coastal structures. Using the right type can prevent costly repairs in the future.

Stainless steel rebar is another option. It offers superior resistance to rust and corrosion. However, it comes with a higher cost. This type is suitable for high-end projects or structures located in harsh climates. Keep in mind that while stainless steel might seem appealing, its expense can complicate budget plans. There are also glass-fiber reinforced polymer rebar options. It is lightweight and non-corrosive, and it's gaining attention in modern construction. However, it may not yet be suitable for all applications.

Choosing the right rebar requires careful consideration of both the project needs and local conditions. Sometimes, the best choice is not the most obvious one. Reflecting on the project's specifics will help guide the decision. Make sure to analyze factors like strength requirements and environmental exposure. Balancing cost and performance will lead to a better construction outcome.

Choosing the right rebar steel for a construction project involves several crucial factors. First, consider the type of structure you are building. Each project has unique demands based on load, height, and environmental factors. For instance, a coastal building may need corrosion-resistant rebar due to salt exposure. Make a list of your project's specific requirements to narrow down your options.

Next, evaluate the steel grade. Rebar comes in different grades, which indicate the steel's strength and yield point. Higher grades generally provide better performance. However, using a higher grade may increase your budget. Balance the need for strength with cost. Sometimes, opting for a lower grade can lead to compromises in safety if not carefully assessed.

Don’t overlook the diameter of the rebar. The size impacts the structural integrity. Thicker bars offer more strength but can be harder to work with. Consider the available space and design constraints. Reflecting on past experiences can also guide your decision. If previous choices led to issues, adjusting your approach is essential. Always think critically about your options to make the best choice for your project.

Choosing the right rebar steel is crucial for the strength of any construction project. Quality standards for rebar are not uniform globally. Different regions have varying specifications. For instance, the American Concrete Institute (ACI) provides guidelines that emphasize essential properties, like yield strength and ductility.

When evaluating rebar, consider its grade. ASTM A615 is commonly used in the U.S. It has standard yield strengths of 40, 60, and 75 ksi. If your project demands higher durability, look for higher grades. Corrosion-resistant options are vital for structures exposed to harsh environments. They can prevent costly repairs.

Tips: Always review the steel’s tensile properties. A tensile test can offer insights into the material's performance under load. Checking certifications ensures compliance with standards. Many projects overlook this crucial step. Make sure to request mill certificates, confirming the steel's quality before purchase.

Rebar selection requires careful assessment. Not all suppliers meet the same quality benchmarks. This inconsistency can lead to significant risks during construction. Always prioritize quality over cost. Remember, investing in quality rebar pays off in the long run.

When planning a construction project, budgeting for rebar steel is crucial. Prices can vary based on market conditions. According to a recent report from the American Institute of Steel Construction, the average cost of rebar fluctuated between $600 to $900 per ton in 2022. This significant price variation can affect overall project costs.

Factors such as location, supplier pricing, and material grades influence expenses. Additionally, localized shortages can lead to spikes in prices. It is essential to source rebar steel well in advance to avoid unexpected costs. In 2023, reports indicated that supply chain disruptions continued, affecting prices. Such variations present a challenge.

Conducting a comprehensive cost analysis is vital. Include factors like transportation, delivery fees, and waste. The estimated waste factor for rebar can be about 10% to account for cutting and leftover materials. With proper planning, these costs can be managed effectively. Ignoring these elements can lead to significant budget overruns. Reflection on past projects can provide insight into cost control. Focusing on details can help mitigate financial risks in construction.

If you need more information about our products or you can’t find what you are looking for, please reach us via our contact form and we will get back to you as soon as possible.

© 2022 MID-CONTINENT STEEL AND WIRE, ALL RIGHTS RESERVED | PRIVACY POLICY | PRIVACY POLICY – CALIFORNIA