News & Notes

The Blog ofMID-CONTINENT STEEL AND WIRE

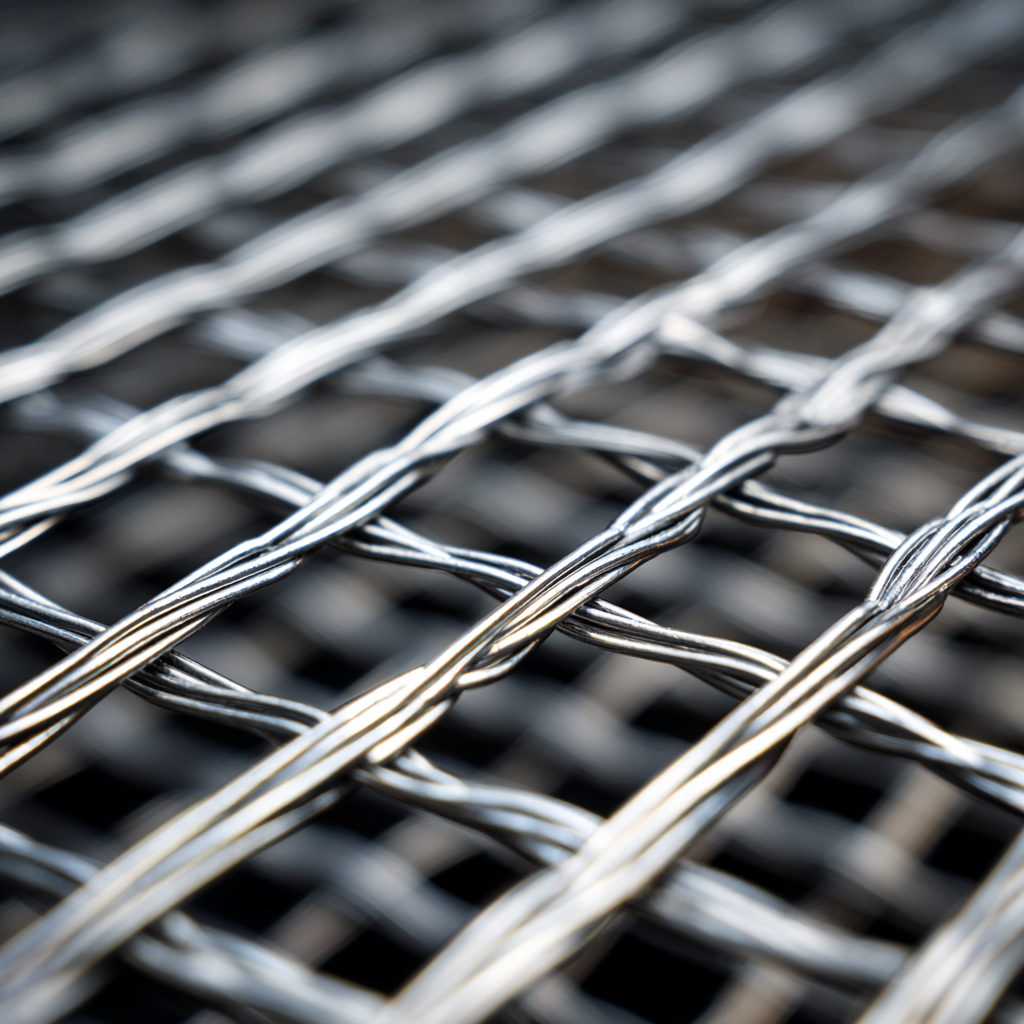

Mesh wire is a versatile material widely utilized across various industries due to its unique properties and multiple applications. In this article, we will explore what mesh wire is, detailing its composition and characteristics that make it an indispensable tool in diverse fields such as construction, agriculture, manufacturing, and beyond. The structure of mesh wire, typically consisting of interconnected strands that form a grid-like pattern, allows for airflow and drainage while providing durability and strength. From reinforcing buildings and fencing livestock to enhancing security and filtration processes, the adaptability of mesh wire serves crucial roles in both practical and aesthetic solutions. By understanding its uses and benefits, readers will gain valuable insights into how mesh wire can be effectively employed in their respective industries, ultimately contributing to improved functionality and safety in their projects.

Mesh wire is a versatile material widely utilized across various industries due to its unique properties and multiple applications. In this article, we will explore what mesh wire is, detailing its composition and characteristics that make it an indispensable tool in diverse fields such as construction, agriculture, manufacturing, and beyond. The structure of mesh wire, typically consisting of interconnected strands that form a grid-like pattern, allows for airflow and drainage while providing durability and strength. From reinforcing buildings and fencing livestock to enhancing security and filtration processes, the adaptability of mesh wire serves crucial roles in both practical and aesthetic solutions. By understanding its uses and benefits, readers will gain valuable insights into how mesh wire can be effectively employed in their respective industries, ultimately contributing to improved functionality and safety in their projects.

Mesh wire is a versatile material widely used across various industries due to its unique composition and physical properties. Typically made from metals such as stainless steel or galvanized iron, mesh wire consists of a network of interwoven strands that create openings of various sizes. This structure not only provides strength and durability but also allows for airflow, drainage, and visibility, making it an ideal choice for diverse applications.

In the construction industry, mesh wire is often employed in reinforcement, such as in concrete slabs and walls, enhancing structural integrity. In agriculture, it serves as fencing to protect crops and livestock while promoting air circulation. Additionally, in the manufacturing sector, mesh wire is utilized for filtration and screening processes, effectively separating materials based on size. The adaptability of mesh wire to meet the specific needs of different industries highlights its essential role in modern applications.

Mesh wire, often referred to as wire mesh, plays a crucial role in various industries, particularly within the construction and engineering sectors. In construction, it is commonly used as reinforcing material in concrete, providing enhanced strength and stability to structures. The grid-like structure of mesh wire allows for even distribution of loads and minimizes the risk of cracking, making it essential in the building of roads, bridges, and high-rise buildings. Builders also use mesh wire in formwork systems to create durable molds for pouring concrete, ensuring the structural integrity of the finished product.

Mesh wire, often referred to as wire mesh, plays a crucial role in various industries, particularly within the construction and engineering sectors. In construction, it is commonly used as reinforcing material in concrete, providing enhanced strength and stability to structures. The grid-like structure of mesh wire allows for even distribution of loads and minimizes the risk of cracking, making it essential in the building of roads, bridges, and high-rise buildings. Builders also use mesh wire in formwork systems to create durable molds for pouring concrete, ensuring the structural integrity of the finished product.

In the engineering sector, mesh wire is utilized in several applications, including filtration and screening processes. Engineers often employ wire mesh for creating filters in HVAC systems or as screens in heavy machinery to prevent the ingress of larger particles while allowing smaller substances to pass. Additionally, mesh wire is vital in the manufacturing of industrial fencing, providing security and safety around construction sites and hazardous areas. Its versatility and strength make it an indispensable material that meets the varying demands of different engineering applications.

Mesh wire is becoming increasingly essential in agriculture for crop protection, offering farmers innovative solutions to mitigate risks associated with pests and environmental factors. According to a report from Markets and Markets, the global agricultural mesh market is projected to reach USD 7.8 billion by 2025, growing at a CAGR of 7.2%. This growth highlights a rising trend toward the adoption of mesh wire in farming practices.

One of the most impactful applications of mesh wire in agriculture is in the creation of protective structures, such as greenhouses and crop nets. These structures not only shield crops from harmful insects and adverse weather conditions but also optimize growing conditions by allowing sunlight and rain to penetrate while maintaining a controlled environment. For instance, a study from the American Society of Agriculture and Biological Engineers indicated that using insect mesh can reduce pest invasion rates by up to 60%, significantly improving crop yield and quality.

Furthermore, mesh wire systems can be utilized in precision farming strategies, where they aid in the deployment of natural pest control methods. By incorporating mesh wire structures into fields, farmers can attract beneficial insects while deterring harmful ones, which aligns with sustainable agricultural practices. As reported by the International Journal of Agricultural Sciences, integrating mesh technology can enhance overall productivity and decrease dependency on chemical pesticides, reflecting a strong move towards eco-friendly farming solutions.

Mesh wire plays a crucial role in both the manufacturing and automotive industries, delivering solutions that enhance product durability and operational efficiency. In the manufacturing sector, mesh wire is often used for filtration, reinforcing, and structural applications. For instance, according to a recent report by Market Research Future, the global market for industrial mesh wire is expected to grow significantly, with an estimated CAGR of 5.2% from 2021 to 2027. This highlights its increasing relevance as industries seek stronger, lighter materials that maintain structural integrity.

In the automotive industry, mesh wire is pivotal for producing parts that benefit from high strength-to-weight ratios. It is commonly utilized in components such as exhaust systems and chassis reinforcements. As reported by the Automotive Industry Action Group, the use of innovative materials, including mesh wire, has contributed to a 15% reduction in vehicle weight, which directly correlates to enhanced fuel efficiency and reduced emissions. This trend towards lightweight, mesh-enhanced structures not only meets stringent regulatory standards but also aligns with consumer demand for eco-friendly vehicles.

When analyzing the material types of mesh wire, steel and plastic stand out as two prominent options, each offering distinct advantages based on the intended application. Steel mesh wire is well-regarded for its durability and strength, making it ideal for industrial settings where heavy loads and high-stress environments are common. Its resistance to wear, heat, and corrosion renders it suitable for construction and mining industries, where longevity and resilience are paramount. Moreover, steel mesh can withstand harsh conditions, promoting structural integrity over time.

On the other hand, plastic mesh wire presents an alternative that excels in flexibility and lightweight characteristics. This type of mesh is often used in agricultural applications, such as fencing or crop protection, where ease of handling and installation are beneficial. Plastic mesh's resistance to rust and corrosion is advantageous in environments with moisture exposure, allowing for long-term use without significant maintenance. Additionally, the non-conductive nature of plastic makes it a preferred choice in electrical applications and settings where safety is a concern. Ultimately, the choice between steel and plastic mesh wire depends on the specific requirements of the industry, balancing factors such as strength, weight, and environmental conditions.

This bar chart illustrates the different applications of steel and plastic mesh wire across various industries, highlighting their advantages and usage frequency.

If you need more information about our products or you can’t find what you are looking for, please reach us via our contact form and we will get back to you as soon as possible.

© 2022 MID-CONTINENT STEEL AND WIRE, ALL RIGHTS RESERVED | PRIVACY POLICY | PRIVACY POLICY – CALIFORNIA