News & Notes

The Blog ofMID-CONTINENT STEEL AND WIRE

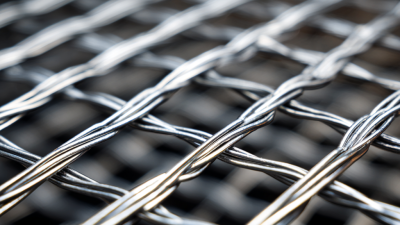

In contemporary construction, the critical role of steel bars, or reinforcing bars (rebar), cannot be overstated. According to the World Steel Association, the global demand for steel bars is projected to reach approximately 1.7 billion metric tons by 2025, driven by the booming construction industry and infrastructure development. Steel bars are essential for enhancing the structural integrity of buildings, bridges, and other construction projects, providing the tensile strength necessary to support considerable loads and endure environmental stresses. Modern engineering practices emphasize the importance of high-quality steel bars, integrating advanced manufacturing techniques to improve performance and longevity. As construction projects continue to evolve with increased complexity, understanding the selection and application of steel bars will be crucial for achieving durability and safety in structural designs. This exploration of steel bars highlights their indispensable role in modern construction and the benefits they bring to both engineers and builders alike.

Steel bars, also known as rebar, play a crucial role in modern construction, providing essential tensile strength and durability to various structures.

Typically made from carbon steel, their design allows for optimal bonding with concrete, enhancing structural integrity. According to the World Steel Association, over 1.6 billion tons of steel are used in construction annually, with fabricated steel bars accounting for a significant portion of this total. Their versatility extends to bridges, highways, and even residential buildings, making them indispensable in today’s architectural landscape.

Steel bars, also known as rebar, play a crucial role in modern construction, providing essential tensile strength and durability to various structures.

Typically made from carbon steel, their design allows for optimal bonding with concrete, enhancing structural integrity. According to the World Steel Association, over 1.6 billion tons of steel are used in construction annually, with fabricated steel bars accounting for a significant portion of this total. Their versatility extends to bridges, highways, and even residential buildings, making them indispensable in today’s architectural landscape.

Tips: When selecting steel bars for a construction project, consider factors such as grade, coating, and diameter. High-strength bars, such as those conforming to ASTM A615, are recommended for projects subject to seismic activity, offering enhanced resilience. Additionally, ensure you maintain proper spacing and placement for maximum load distribution, which can significantly reduce the risk of structural failures.

Understanding the manufacturing standards and specifications for steel bars is vital. The American Concrete Institute advises using the right bar sizes and spacing to combat common issues like cracking and deformation. As construction methodologies evolve, staying informed about innovations in steel bar technology, such as corrosion-resistant coatings, can lead to enhanced longevity and safety in your builds.

The type of steel bars used in construction plays a crucial role in determining the structural integrity of a building. Among the various types of steel bars available, the most commonly used are high-strength deformed bars (HRB), mild steel bars, and stainless steel bars. High-strength deformed bars are favored for their superior bonding properties and the ability to withstand higher loads, making them ideal for reinforced concrete structures. Their unique surface deformation enhances grip between the bar and concrete, ensuring stability and safety under stress.

In contrast, mild steel bars offer excellent ductility, which allows them to deform significantly before failure. This quality is particularly beneficial in seismic zones where buildings must maintain flexibility. Meanwhile, stainless steel bars, while more expensive, provide exceptional resistance to corrosion, making them suitable for structures exposed to harsh environmental conditions. By understanding the properties and applications of these different types of steel bars, engineers can select the most appropriate materials to enhance the durability and safety of modern constructions.

Steel bar reinforcement is a critical aspect of modern construction, playing a pivotal role in enhancing the structural integrity of buildings and infrastructure. Proper techniques for implementing steel bar reinforcement can significantly influence the durability and strength of concrete structures. One essential method involves the careful positioning of steel bars within concrete forms to ensure optimal load distribution and resistance to tension and compression forces. This is often achieved through precise calculations and engineering assessments that take into account the specific load requirements of the structure.

Additionally, the bonding between steel bars and concrete is crucial for effective reinforcement. Techniques such as proper concrete cover and the use of high-quality materials can enhance this bond, preventing common issues like corrosion and spalling. Furthermore, adhering to industry standards and codes during the installation process ensures that the reinforcement meets safety and structural performance requirements. By focusing on these proper techniques for steel bar reinforcement, construction professionals can unlock the full potential of steel bars, contributing to safer and more resilient structures.

This chart illustrates key properties of steel bars used in modern construction, highlighting their vital role in ensuring structural integrity. The data encompasses strength, ductility, corrosion resistance, weight, and cost, which are essential factors in the structural engineering field.

Steel bars, commonly used in reinforced concrete structures, play a crucial role in enhancing the structural integrity of buildings and infrastructure. According to the American Institute of Steel Construction (AISC), steel bars improve the tensile strength of concrete, allowing for the construction of longer spans and taller buildings without compromising safety. Recent studies indicate that structures utilizing steel reinforcement can endure more significant loads, exhibit greater ductility, and resist seismic forces up to 30% better than unreinforced counterparts.

Tip: When selecting steel bars, ensure compliance with relevant standards such as ASTM A615, which specifies grades, mechanical properties, and chemical composition.

Moreover, the impact of steel bars on structural integrity goes beyond load-bearing capabilities. They also contribute to a structure’s durability and resistance to environmental factors such as corrosion. The National Institute of Standards and Technology (NIST) reported that the use of properly treated steel bars can significantly reduce maintenance costs and extend the lifespan of structures by up to 50%.

Tip: Regular inspections and maintenance of steel reinforcement and protective measures can further enhance longevity and performance.

The construction industry is witnessing innovative trends in the usage of steel bars that are pivotal to achieving sustainability in modern building practices. Recent studies highlight the development of reinforced concrete structures that integrate various types of concrete to improve structural integrity while minimizing environmental impact. This approach benefits from advanced production technologies that enhance the performance of building materials, aligning with the overarching goal of sustainable construction.

Moreover, the growing emphasis on sustainable waste management underscores the need for effective recycling and reuse of construction materials, including steel bars. By implementing strategies that prioritize the circular economy, the construction sector is poised to reduce carbon footprints while maintaining durability and strength in structures. The rising market for structural steel, driven by urbanization and sustainability initiatives, reflects the industry's commitment to integrating innovative materials that resist corrosion and provide high quality. As the industry evolves, the role of steel bars will remain central in constructing efficient, resilient buildings that meet the challenges of modern urban development.

| Dimension | Common Sizes (mm) | Typical Applications | Sustainability Impact |

|---|---|---|---|

| Tensile Strength | 10-35 | Reinforcement in concrete structures | Recyclable and reduces material waste |

| Weight | 6-20 | Frames for buildings and bridges | Lower performance of lighter materials |

| Corrosion Resistance | Varied (coated options) | Marine structures | Extends lifespan, reduces maintenance |

| Flexural Strength | 12-20 | Beams and columns | Supports sustainable design through efficiency |

If you need more information about our products or you can’t find what you are looking for, please reach us via our contact form and we will get back to you as soon as possible.

© 2022 MID-CONTINENT STEEL AND WIRE, ALL RIGHTS RESERVED | PRIVACY POLICY | PRIVACY POLICY – CALIFORNIA