News & Notes

The Blog ofMID-CONTINENT STEEL AND WIRE

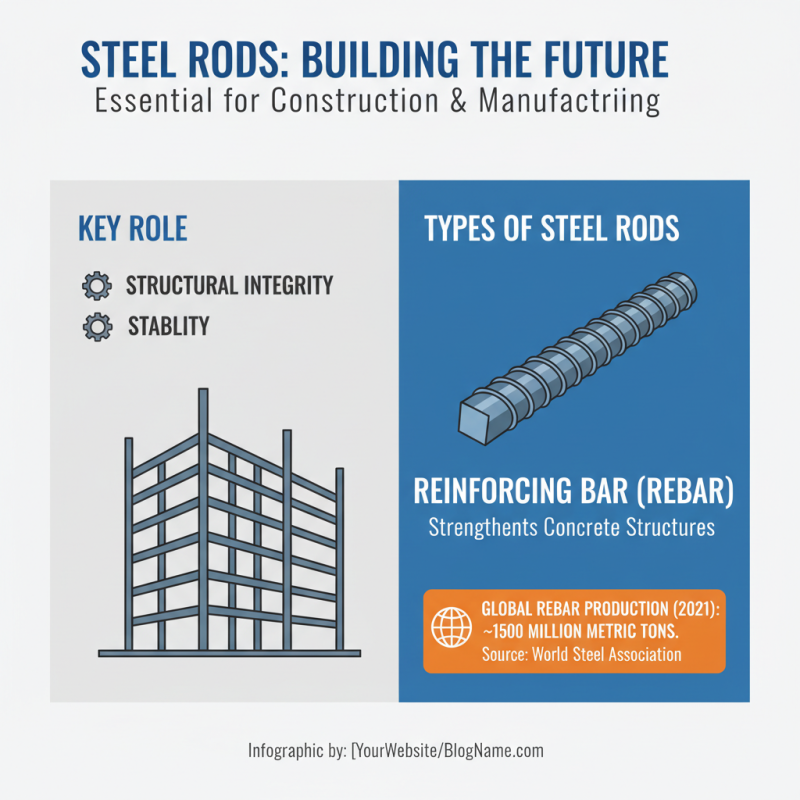

In the realm of construction and manufacturing, steel rods serve as essential components that provide strength and stability to a variety of structures. According to industry expert Dr. Emily Carter, a structural engineer with over 20 years of experience, "Steel rods are the backbone of modern infrastructure; their versatility and durability make them indispensable in reinforcing concrete and other materials." This statement underscores the pivotal role that steel rods play in enhancing the integrity of buildings, bridges, and other critical infrastructures.

The utilization of steel rods is not limited to just construction; they are also crucial in manufacturing processes where precision and reliability are paramount. Their properties, including high tensile strength and resistance to bending, allow them to be effectively employed in situations where traditional materials would fail. Whether in high-rise buildings or intricate machinery, steel rods are designed to withstand significant stress while maintaining their structural integrity. As we delve deeper into the applications and benefits of steel rods, it becomes clear that their importance in both construction and manufacturing cannot be understated.

A steel rod is a long, cylindrical piece of metal primarily composed of iron, mixed with a small amount of carbon to enhance its strength and durability. The carbon content in steel typically ranges from 0.02% to 2.1% by weight, which gives steel its distinct properties, making it a popular choice in various construction and manufacturing applications. Steel rods come in various diameters and lengths, and are manufactured through processes such as rolling or forging, creating a robust material capable of withstanding significant stress.

In construction, steel rods play a critical role as reinforcement bars, often used in concrete structures. They provide necessary tensile strength, ensuring that concrete can bear loads without cracking or failing. In manufacturing, steel rods are utilized in producing a plethora of items, ranging from fasteners and tools to machinery components. Their versatility and high strength-to-weight ratio make them indispensable in modern construction and industry.

Tip: When selecting steel rods for a project, consider the specific requirements such as tensile strength and corrosion resistance to ensure optimal performance. Always consult the relevant engineering standards and guidelines for appropriate applications.

Tip: Always wear appropriate protective gear when handling steel rods, as their edges can be sharp, and improper handling can lead to injuries. Safety is a priority in both construction and manufacturing environments.

| Dimension | Value |

|---|---|

| Material | Steel |

| Common Sizes | ¼ inch to 2 inches in diameter |

| Tensile Strength | Up to 200 ksi (kilopounds per square inch) |

| Uses in Construction | Reinforcement in concrete, support structures |

| Uses in Manufacturing | Machinery components, tools, fasteners |

| Corrosion Resistance | Galvanization or coating available |

| Standard Compliance | ASTM, ISO standards |

Steel rods play a crucial role in construction and manufacturing, serving as essential components for structural integrity and stability. There are several types of steel rods commonly used in these industries, each designed for specific applications. One of the most prevalent types is the reinforcing bar, or rebar, which is typically employed to strengthen concrete structures. According to the World Steel Association, the global production of rebar reached approximately 150 million metric tons in 2021, underscoring its significance in the construction sector.

Another important type of steel rod is the round steel bar, often used in machining and manufacturing processes. These bars are characterized by their uniform cylindrical shape and are available in various diameters, making them suitable for applications ranging from automotive parts to building fittings. The American Iron and Steel Institute reports that the demand for round steel bars is projected to grow by 3% annually, driven by expanding construction and automotive industries. Additionally, square and flat steel bars are utilized for applications that require greater surface contact, enhancing their usability in fabrication and construction projects. These varied types of steel rods are integral to meeting the diverse needs of modern construction and manufacturing activities.

Steel rods are critical components in both construction and manufacturing due to their unique properties and numerous benefits. One of the key properties of steel rods is their high tensile strength, which makes them ideal for reinforcing concrete in buildings and bridges. According to the American Institute of Steel Construction (AISC), steel's tensile strength can exceed 400 MPa, allowing structures to withstand heavy loads and environmental stresses. Additionally, steel rods offer excellent ductility, which means they can deform under stress without breaking, providing resilience in seismic applications.

The benefits of using steel rods go beyond strength and durability. Their corrosion resistance, when treated properly, enhances their longevity, reducing maintenance costs for constructions. A report from the Steel Construction Institute states that proper coating can extend the life of steel rods by up to 50 years. Furthermore, steel rods are recyclable, contributing to sustainability efforts in construction and reducing the carbon footprint associated with new material production.

Tip: When selecting steel rods for construction, consider factors like yield strength and elongation based on project specifications to ensure optimal performance. Additionally, collaborating with experienced engineers will provide insights into the best practices for incorporating steel rods in designs, ultimately saving time and resources.

Steel rods are fundamental components in various construction projects, prized for their strength and durability. One of the most common applications of steel rods is in reinforced concrete structures. They are strategically placed within concrete to enhance its tensile strength, which is crucial for the stability and longevity of buildings, bridges, and other infrastructures. The rods ensure that the concrete can withstand not only vertical loads but also lateral forces, such as wind and earthquake pressure.

In addition to reinforcement, steel rods are also used in the fabrication of frameworks for commercial and residential constructions. They serve as structural supports in scaffolding systems, providing the necessary stability during the building process. Furthermore, steel rods find application in machinery and equipment, where they are utilized to create robust frameworks and joints. Their versatility extends to multiple structural designs, making them indispensable in both small-scale projects and large engineering ventures.

Steel rods are integral to various manufacturing processes due to their durability and versatility. They are commonly employed in construction, automotive, and aerospace sectors. The production of steel rods typically involves several key processes including melting, casting, and rolling. Initially, raw materials such as iron ore and scrap metal are melted in a furnace to create molten steel. This molten steel is then poured into molds to form semi-finished products like billets or blooms, which are further processed into steel rods.

Once the steel billets are formed, they undergo a method called hot rolling, where the material is heated and passed through a series of rollers to achieve the desired diameter and length. This process not only shapes the rods but also enhances their mechanical properties, making them suitable for demanding applications. Further refining processes such as cold drawing may also be applied, which involves pulling the steel rods through a die to achieve precise dimensions and finish.

Additionally, various surface treatments can be employed to improve corrosion resistance or surface hardness, thus extending the lifespan and performance of the steel rods in their respective applications.

If you need more information about our products or you can’t find what you are looking for, please reach us via our contact form and we will get back to you as soon as possible.

© 2022 MID-CONTINENT STEEL AND WIRE, ALL RIGHTS RESERVED | PRIVACY POLICY | PRIVACY POLICY – CALIFORNIA