News & Notes

The Blog ofMID-CONTINENT STEEL AND WIRE

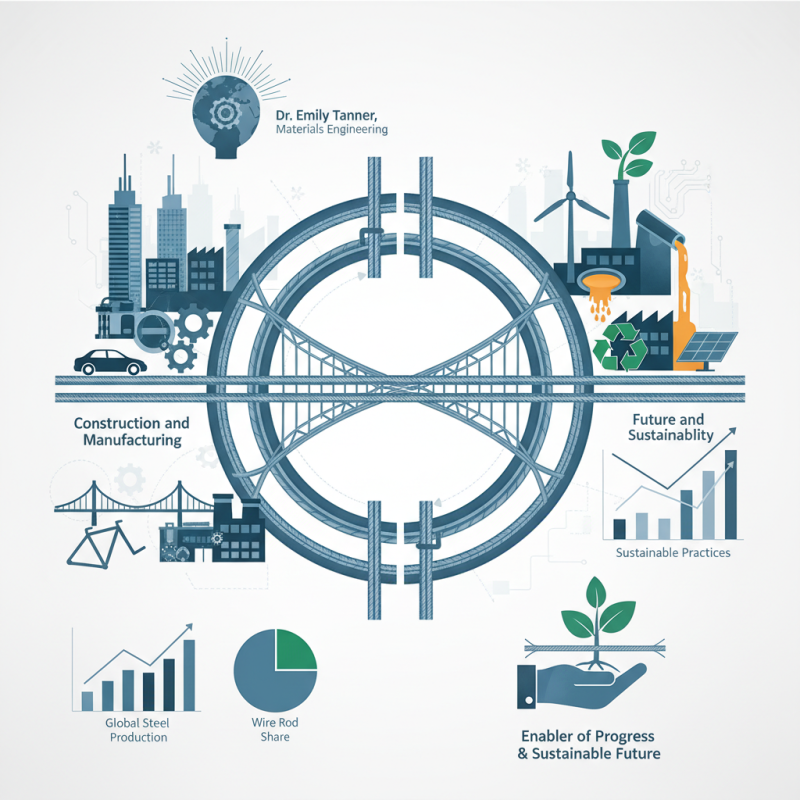

In the construction and manufacturing industries, few materials are as vital as steel wire rod. According to a recent report by the World Steel Association, global steel production reached 1.9 billion tons in 2022, with wire rod specifically accounting for a significant portion. This essential component contributes to structures, machinery, and everyday products, underscoring its importance.

Experts like Dr. Emily Tanner, a leading figure in materials engineering, state, "Steel wire rod is the backbone of modern infrastructure." This underscores its critical role in ensuring structural integrity and reliability. Steel wire rod is used in various applications, from reinforced concrete to automotive manufacturing. It is more than just a product; it is an enabler of progress and innovation.

However, the industry faces challenges. Fluctuating prices and environmental concerns demand a reevaluation of production methods. Companies must work towards sustainable practices to meet future demands. The reliance on steel wire rod highlights not just its importance but also the responsibility we carry for a more sustainable future.

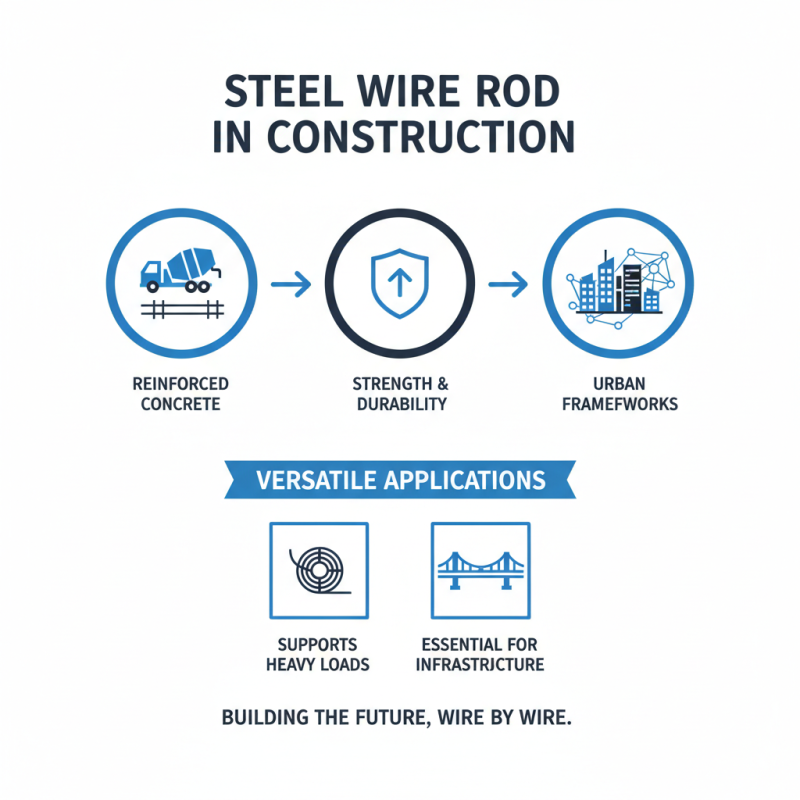

Steel wire rod plays a crucial role in construction projects. Its versatility makes it suitable for various applications. Builders often rely on it for reinforced concrete structures. This not only enhances strength but also increases durability. In urban construction, steel wire is a common sight. It is weaved into frameworks to support heavy loads.

The unique ability of steel wire rod to withstand tension adds to its value. From bridges to high-rise buildings, it is a staple. However, sourcing quality steel wire can be challenging. Not all suppliers meet the necessary standards. This inconsistency can lead to structural weaknesses down the line. Projects may take longer if issues arise.

Moreover, the installation of steel wire rod requires skilled labor. Not everyone has the training to handle it properly. Mistakes can prove costly. Workers must be vigilant and precise in their tasks. A single oversight could compromise the entire structure. Continuous training and attention to detail remain vital for success in the construction industry.

Steel wire rod plays a crucial role in various manufacturing processes. It serves as the backbone for many products in construction and other industries. The versatility of steel wire rod allows it to be drawn into wires, making it essential for creating components like cables, springs, and fasteners. Each of these products has unique requirements, showcasing the adaptability of steel wire in meeting diverse needs.

When working with steel wire rod, it's essential to consider its tensile strength. This property directly impacts the durability of the final product. For instance, in construction, strong wires ensure better structural integrity. However, not all steel wire rods are created equal. Quality can vary significantly, which underscores the importance of sourcing materials carefully.

Tips: Always test materials before use. This step can save time and resources later. Consider local suppliers for better quality control. Engage in discussions with manufacturers about specifications to ensure you meet your project’s requirements. Remember, sometimes "good enough" isn’t enough. Always strive for excellence in your raw materials to enhance your end products.

| Dimension | Description | Applications | Benefits |

|---|---|---|---|

| Diameter | Typically ranges from 5.5 mm to 12 mm | Reinforcement in concrete, wire ropes | High tensile strength, durability |

| Material Composition | Mostly low-carbon steel | Production of wires, cables, nails | Corrosion resistance, cost-effective |

| Production Process | Manufactured through hot-rolling process | Automotive components, construction hardware | Efficient production, uniform quality |

| Market Demand | Increasing demand in construction and manufacturing | Infrastructure projects, machinery manufacturing | Supports economic growth, employment opportunities |

| Sustainability | Recyclable material | Green building initiatives, eco-friendly projects | Reduced environmental impact, resource conservation |

Steel wire rod is a critical component in various industries, especially construction and manufacturing. Different types cater to specific applications. For example, low-carbon steel wire rods are ideal for producing meshes and reinforcement bars. These rods are malleable and easy to shape, making them perfect for building foundations.

In contrast, high-carbon steel wire rods offer greater strength. They are often used in the automotive and aerospace sectors. Their rigidity allows them to withstand high-stress conditions, providing safety and reliability. Specialty wire rods may have unique coatings or treatments. These features enhance corrosion resistance, which is vital for outdoor structures.

**Tips:** Always consider the environment when selecting wire rods. The right choice can minimize maintenance costs. Also, check local regulations on materials. Compliance is essential for successful projects. Using the wrong rod type can lead to safety hazards. Remember, not all rods fit every task well.

Steel wire rod plays a pivotal role in construction and manufacturing.

This material is highly versatile and useful in various applications. It provides exceptional strength and durability,

making it ideal for building structures. Steel wire rod can withstand heavy loads. Some other materials simply cannot match

this capacity.

The advantages of using steel wire rod are numerous. It is resistant

to corrosion when treated properly. This quality ensures longevity in outdoor settings. Additionally, steel wire rod is

often more cost-effective over time. It requires less maintenance than alternatives like wood, which may rot or degrade.

However, there are some challenges. The production process can generate waste and have environmental impacts. Not every project

may require the robustness that steel wire rod offers. In those situations, reevaluating material choice is essential.

Finding the right balance between strength and sustainability can lead to a more responsible approach in construction.

The future trends in steel wire rod usage indicate a shift towards more sustainable and efficient practices in construction and manufacturing. With growing environmental concerns, industries seek materials with lower carbon footprints. Steel wire rod is increasingly being produced with recycled content, reducing waste and energy consumption. This shift is essential not only for meeting regulations but also for appealing to eco-conscious consumers.

Another trend is the customization of steel wire rod to meet specific structural needs. Manufacturers are developing high-strength variants that require less material but provide excellent performance. This innovation can lead to lighter structures and lower transport costs. However, this places pressure on manufacturers to constantly innovate and adapt to changing demands. Adapting to new technologies can be costly and time-consuming.

Like any trend, challenges persist. Some may overlook the importance of quality in favor of lower costs. This can lead to structural weaknesses in buildings and infrastructure. Striking a balance between cost and quality will be crucial. As industries evolve, steel wire rod's role will not only remain essential but will also become more complex and multifaceted.

If you need more information about our products or you can’t find what you are looking for, please reach us via our contact form and we will get back to you as soon as possible.

© 2022 MID-CONTINENT STEEL AND WIRE, ALL RIGHTS RESERVED | PRIVACY POLICY | PRIVACY POLICY – CALIFORNIA