News & Notes

The Blog ofMID-CONTINENT STEEL AND WIRE

Choosing the right steel for your project is crucial. Quality steel can make or break your construction plans. According to John Walker, a leading expert in the steel industry, "The choice of steel determines the durability of your project." His words remind us that quality steel is not merely an option; it is an essential element.

When selecting steel, consider various factors. The grade of steel, its structural properties, and how it performs under pressure matter. For instance, using high-quality steel enhances a structure's longevity. However, cheap alternatives may seem appealing but often lead to costly repairs. Decisions made in haste can haunt your project later.

Moreover, not all suppliers are equal. Your project deserves the best. Trustworthy suppliers usually provide test results, certifications, and expert advice. Ignoring these details could result in future setbacks. Quality steel represents a commitment to safety and excellence. Ultimately, the best choice is one that supports your project's goals. Reflecting on these aspects is vital for success.

When selecting steel for a project, understanding its types and properties is vital. There are several types of steel:

carbon, alloy, stainless, and tool steel. Each comes with unique characteristics.

For instance, carbon steel is strong and affordable. However, it can rust easily without proper coating.

On the other hand, stainless steel is corrosion-resistant and ideal for kitchen applications. Yet, it is often more expensive.

Alloy steel is a versatile option. It contains additional elements that enhance its properties.

This steel can withstand high temperature and pressure. However, the specific benefits depend on the added elements.

Finally, tool steel is essential for making sharp tools. It's tough but can be brittle if not treated correctly.

Choosing the wrong type may compromise your project's success.

Overall, selecting steel requires careful consideration.

Consider environmental factors, cost, and intended use. Reflect on how the steel will perform over time.

Making an informed choice can lead to better project outcomes.

Think about future maintenance as well; some steels may need more care than others.

Choosing the right steel for your project requires careful consideration. Think about the specific properties you need. Different projects demand different strengths. Corrosion resistance, weight, and flexibility are key factors. For outdoor structures, weather-resistant steel might be necessary. You don't want your hard work to rust away.

Be mindful of the steel's tensile strength. Some projects require high strength for load-bearing applications. Check the thickness and gauge of the steel too. A thicker steel may be more durable but could be heavier, impacting design. Reflect on your project's requirements and constraints. Are you sure about your choices?

Cost is also a concern. Cheaper steel may seem attractive, but it can lead to problems. You might end up spending more on repairs later. Test your options carefully before deciding. Trust your instincts but don’t overlook important details. Each choice impacts the overall project quality. Make sure every aspect aligns with your goals.

| Steel Type | Key Characteristics | Common Uses | Strength (MPa) | Corrosion Resistance |

|---|---|---|---|---|

| Mild Steel | Ductile, weldable, and malleable | Construction, automotive | 250-400 | Low |

| Stainless Steel | Corrosion-resistant, durable | Kitchenware, medical instruments | 520-800 | High |

| Carbon Steel | Higher strength than mild steel | Making tools, machinery | 400-600 | Medium |

| Alloy Steel | Improved properties through alloying | Aerospace, automotive | 600-1200 | Variable |

| Tool Steel | Hard, wear-resistant | Tool manufacturing | 600-1200 | Low |

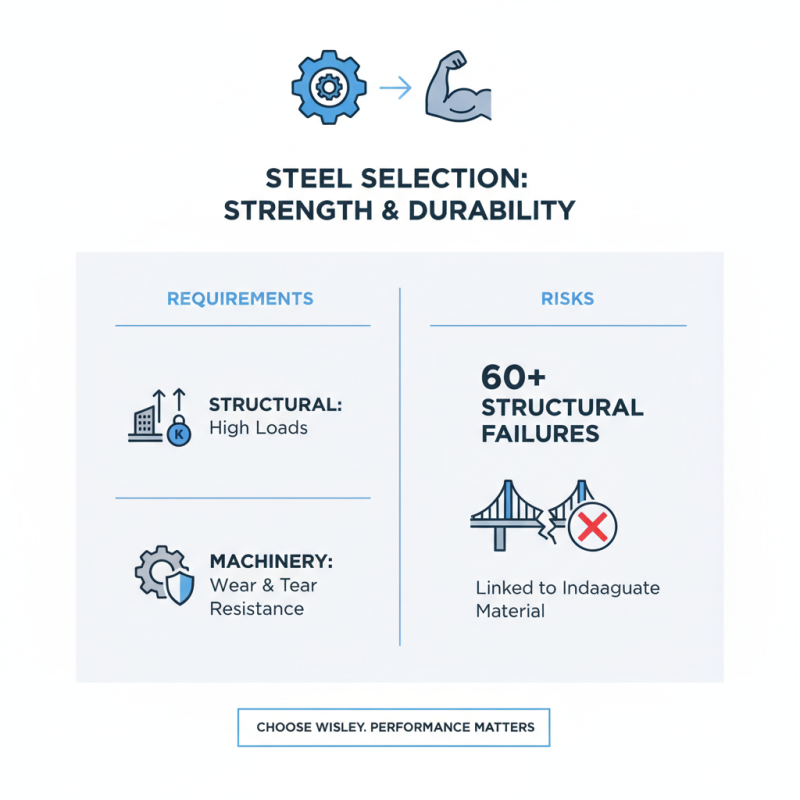

When selecting steel for a project, evaluating strength and durability requirements is crucial. Different applications demand varying levels of performance. For instance, structural steel must withstand high loads, while steel for machinery needs to resist wear and tear. According to a recent industry report, over 60% of structural failures are linked to inadequate material selection.

The tensile strength of steel is a key factor. For construction purposes, steel grades like S235 and S355 provide distinct strength levels. The former offers a minimum yield strength of 235 MPa, while the latter reaches 355 MPa. Choosing the correct grade can prevent costly failures. Still, many underestimate the importance of corrosion resistance. This oversight can lead to significant long-term maintenance costs.

In some cases, even high-strength steel can fall short. It's vital to consider factors like environmental exposure and application duration. A study found that 40% of projects encountered unexpected performance issues, often due to poor material choices. Reflecting on past failures can enhance future decisions. Always revisit strength and durability requirements when selecting steel to ensure a successful outcome.

When selecting steel for your project, cost and availability are crucial factors. The price can significantly impact your budget. Different types of steel come with varying costs based on their properties. For instance, stainless steel generally costs more due to its corrosion resistance.

Availability can be tricky. Some specialized steels may not be readily available in your area. This can lead to delays in your project timeline. Consider local suppliers and their stock. A common type might be more accessible than a specialty option. Always check for lead times and how they align with your deadlines.

While it's tempting to focus solely on quality, balancing cost and availability often leads to better decision-making. You may need to adjust your expectations for the best deal. This sometimes means reassessing the type of steel you originally planned to use. A more common type could meet your needs without sacrificing quality too much.

Sourcing quality steel suppliers requires careful consideration. Look for suppliers who have positive reviews and strong industry experience. A good reputation often indicates reliability and quality of materials. Visit their facilities, if possible. This gives insights into their production processes.

Ask for samples before making larger purchases. Evaluate the steel's grade and strength. Remember, not all steel is created equal. Some suppliers might offer lower prices, but the quality may suffer. Always compare materials with your project requirements in mind.

Another tip is to build a relationship with your suppliers. Communication can enhance trust and clarify expectations. Discuss your needs and timelines openly. It's okay to have questions or concerns. Not every interaction will be perfect, and it’s essential to be adaptable. Reflect on what your project truly requires and make adjustments as needed.

If you need more information about our products or you can’t find what you are looking for, please reach us via our contact form and we will get back to you as soon as possible.

© 2022 MID-CONTINENT STEEL AND WIRE, ALL RIGHTS RESERVED | PRIVACY POLICY | PRIVACY POLICY – CALIFORNIA